CONCRETE SCANNING & INVESTIGATION SPECIALISTS

Concrete Scanning ○ Corrosion Inspection ○ Core Sample Testing ○ Structural Investigation

- GPR Concrete Scanning

- Corrosion Inspection

- Core Sample Testing, and

- Structural Investigation

WHO WE ARE

Conscan is a 100% Australian owned and operated company with over 20 years’ experience in concrete scanning and coring.

Whether you are assessing the strength of a concrete slab, trying to pinpoint the right place to cut or drill, assess the rate of corrosion or the quality of the concrete we give you the information you need.

Conscan is committed to ensuring the health and safety of our people while maximising our productivity and capabilities in the workplace. All of our team are fully trained and experienced to comply with our Safety Management System.

Our attention to detail along with our commitment to quality service, continual training and our record of client satisfaction makes Conscan a reliable partner for your next project.

Our Vision

Undertaking any new construction and renovation projects comes with the potential issue of needing to cut or core concrete slabs. With this comes the risk of striking electrical and communications conduits, post tension cables and rebar. Mistakes such as these can add strain to your financial budget and time schedule; not to mention, creating a safety hazard for your employees. Our highly skilled and experienced technicians respond quickly and efficiently to any service request. The outcome of our professional services is accurate and prompt scanning that mitigates the potential risks and keeps your employees safe.

WE SPECIALISE IN THE INVESTIGATION OF

- Corrosion/concrete Cancer Location

- Honeycombing Detection

- Rate Of Corrosion

- Void And Delamination Detection

- Fiber Concrete

- Cover Depths

- Concrete Hit Prevention

- Imaging Of Closely Spaced Rebars

- Post Tension Defects

- Rebar & Diameter

- Bonding Assessment

- Thickness Measurement

- Cracks & Depth Measurement

- Strength Assessment

WHERE WE ARE

Brisbane ○ Gold Coast ○ Sunshine Coast ○ Ipswich ○ Toowoomba ○ Interstate

At Conscan, our services are available to residential, commercial, and industrial clients across all areas of South East Queensland. Our experienced operators work 24 hours a day, 7 days a week. We take pride in our ability to offer a great service every time. We have the people, resources, skill and experience to complete any job.

WHY CHOOSE US

Undertaking any new construction and renovation projects comes with the potential issue of needing to cut or core concrete slabs. With this comes the risk of striking electrical and communications conduits, post tension cables and rebar which can be hidden in the concrete wall or floor. Mistakes such as these can add strain to your financial budget and time schedule; not to mention, creating a safety hazard for your construction team.

Concrete scanning is a cost-effective, non-destructive method of obtaining information on items within concrete structures or below the ground. We are able to safely locate steel reinforcement, post tension cables and anomalies. It allows construction industry professionals to make informed decisions prior to concrete cutting and core drilling.

At Conscan, our highly skilled and experienced technicians respond quickly and efficiently to any request for our concrete scanning service. The outcome of our professional services is accurate and prompt scanning that mitigates the potential risks and keeps your employees safe.

OUR SERVICES

CONCRETE SCANNING

CONCRETE SCANNING

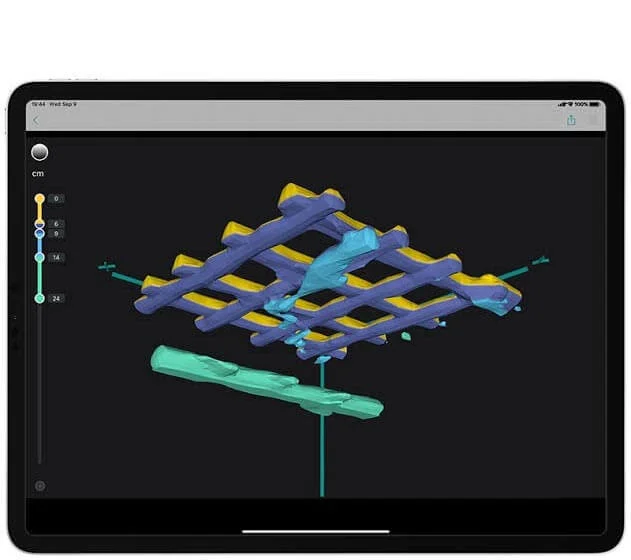

Concrete scanning is crucial for analysing the contents of concrete structures. This includes the depth of the concrete itself as well as information about the rebar such as its spacing and position within the concrete.

Our non-invasive Ground Penetrating Radar (GPR) technology can find steel reinforcement, post-tension cables, live power, conduit and many other items. Concrete analysis thus gives engineers the information they need to make decisions regarding the structure. This allows accuracy to cut into concrete surfaces with confidence, knowing that any hidden items have been identified.

- Scanning for drilling and cutting concrete

- Discovering any voids in the concrete walls, ceilings, subgrade, or slab

- Pinpointing the location of objects such as rebar and post-tension cables

- Establishing the position of embedded power cables within the concrete

- Slab mapping and depth sizing

- Identifying structural steel elements

- Inspection purpose concrete scanning

CORROSION INSPECTION

CORROSION INSPECTION

Concrete buildings are vulnerable to corrosion due their reliance on steel bars or mesh for reinforcement. Exposure to air and water causes the steel to expand and corrode. As the damage to the internal steel framework worsens, the surrounding concrete also starts to fail. This is known as concrete spalling or concrete cancer.

Concrete is porous, so it absorbs the carbonic acid created during the corrosion process. This accelerates the concrete spalling and eventually leads to expensive property damage. Common signs of spalling include cracking, flaking, crumbling, rust stains or bubbling on the concrete or cement render and leaks in the roof and walls.

- Detection of corrosion in reinforcement

- Measurement of rebar corrosion rate

- Evaluation of corrosion potential of rebar

- Measurement of in-situ electrical resistivity

- Assessment of concrete durability

CORE SAMPLING AND TESTING OF CONCRETE

CORE SAMPLING AND TESTING OF CONCRETE

With our professional concrete scanning equipment, we can accurately measure the thickness of a concrete slab, map size reinforcement and locate appropriate sites for core samples to be taken. We offer chemical analysis of core samples, such as chloride and sulphate intrusion profiles, as well as carbonation. Testing involves placing a steadily increasing load down the length of the core sample until the sample fractures and breaks. The load at which the concrete collapses will indicate its compressive strength, and from this can be calculated an array of useful information. Crush testing of core samples can be provided and analysed to measure flex and deformation in our National Association of Testing Authorities Australia (NATA) accredited facility.

Our NATA accredited laboratory will then provide a report of the outcome of the crush test which Conscan will forward on to the customer. Onsite hardness testing can also be accommodated using our advanced NDT testing equipment and following relevant industry standards.

- Strength and density determination

- Depth of carbonation of concrete

- Chemical analysis

- Water/gas permeability

STRUCTURAL CONCRETE INVESTIGATION

STRUCTURAL CONCRETE INVESTIGATION

Non-Destructive Testing (NDT) is an important method for assessing the condition and integrity of existing reinforced structures. After visual inspection, NDT can identify the location of the issue, the rate at which damage has occurred and the severity so that appropriate action may be taken to prevent further deterioration.

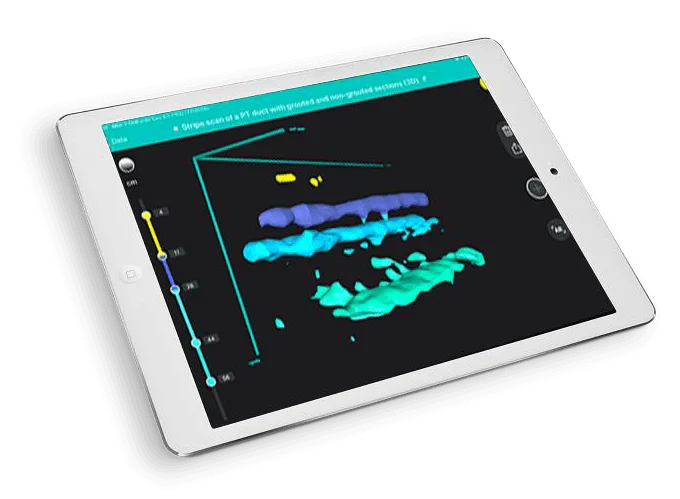

We use Ultrasonic Transducers to create highly intuitive images of the internal structure of the concrete. This ultrasonic technique is highly sensitive to air voids, cracks and honeycombing with the concrete while still providing images of metallic items in most cases.

- Location of defects such as voiding or delamination of concrete

- Thickness measurements of concrete elements

- Detection of objects in conventional or steel fibre reinforced concrete

- Evaluate the grouting of post tension tendon ducts

CONCRETE CUTTING

CONCRETE CUTTING

At Conscan, we provide professional concrete cutting services for residential, commercial, and industrial projects across Brisbane and South East Queensland. Whether you need precise cuts for renovations, demolitions, or new construction, our expert team delivers fast, accurate, and cost-effective solutions tailored to your project needs.

Our Concrete Cutting Services

We offer a full range of concrete cutting solutions, including:

- Road Sawing – Ideal for driveways, roads, and large slabs.

- Wall Sawing – Precise vertical and horizontal cuts for windows, doors, and modifications.

- Hand Sawing – Perfect for small, hard-to-reach areas.

- Wire Sawing – For large-scale cutting of thick or reinforced concrete.

- Core Drilling – Clean and accurate circular holes for plumbing, electrical, and HVAC systems.

- Precise & Controlled Cutting – Avoid unnecessary damage to surrounding structures with clean, straight cuts.

- Suitable for Any Material – We can cut through reinforced concrete, brick, stone, asphalt, and masonry with ease.

- Low-Noise & Low-Vibration – Our cutting methods minimize disruption, making them ideal for occupied buildings and sensitive environments.

- Fast & Efficient – We use state-of-the-art equipment to reduce project timelines and costs.

- Custom Solutions – Whether you need floor sawing, wall sawing, hand sawing, or core drilling, we have the right tools for the job.

- Safe & Professional – Our highly trained operators follow strict safety and industry standards to ensure the best results with no compromises.

WIRE SAWING

WIRE SAWING

At Conscan, we specialise in wire sawing services for industrial, commercial, and residential projects across Brisbane and South East Queensland. Whether you need to cut through reinforced concrete, stone, or steel structures, our diamond wire sawing technology provides a fast, efficient, and non-vibrational solution that ensures precision and minimal disruption to surrounding structures.

- Ideal for Large-Scale & Complex Jobs – Perfect for cutting bridges, piers, foundations, and walls where traditional saws can’t reach.

- Minimally Invasive – Unlike jackhammers or impact tools, wire sawing is a low-noise, low-vibration method, reducing damage to surrounding structures.

- Unlimited Cutting Depth – Wire sawing is not restricted by depth, making it ideal for massive concrete blocks and thick slabs.

- Precise & Clean Cuts – Achieve smooth, straight cuts with minimal dust and debris, ensuring a safer and cleaner worksite.

- Wet & Dry Cutting Options – We can tailor our wire sawing services for indoor or outdoor environments, including underwater applications.

WALL SAWING

WALL SAWING

At Conscan, we offer specialist wall sawing services for construction, renovation, and demolition projects across Brisbane and South East Queensland. Whether you need precise openings for doors, windows, ventilation, or structural modifications, our diamond wall sawing technology ensures clean, straight cuts with minimal noise, dust, and vibration.

- Precision Cutting – Achieve clean, accurate cuts without overcutting or unnecessary damage to surrounding areas.

- Ideal for Openings & Modifications – Perfect for creating doors, windows, lift shafts, ventilation ducts, stairways, and access points.

- Versatile & Adjustable – Can be used on vertical walls, floors, ceilings, and even sloped surfaces.

- Minimal Disruption – Low noise, dust, and vibration levels make it an excellent choice for occupied buildings or sensitive environments.

- Works on Thick & Reinforced Concrete – Our high-powered diamond blades can cut through heavily reinforced concrete and masonry up to 730mm deep.

- Fast & Cost-Effective – Wall sawing is a quick, efficient method that reduces labour time and overall costs compared to traditional demolition techniques.

REPORTING

Conscan provide our clients with reporting as an added service. Our reports contain information on the areas scanned, advice on slab thickness, reinforcing patterns and any other anomalies in the test area. These reports can be distributed to other trades and professionals involved in the project.